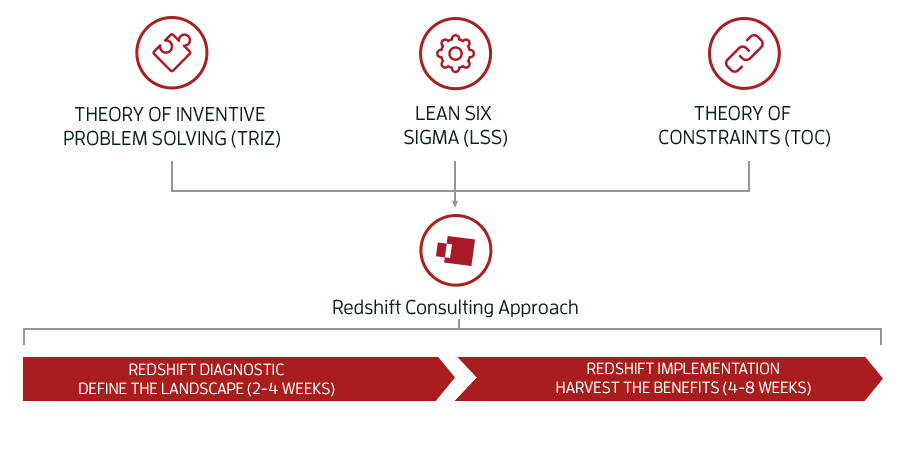

At Redshift, we view business challenges as contradictions that exists between two competing forces: market to market, market to business, or business to business. Our approach to innovative problem solving is to identify and remove the contradictions, without trade-offs or compromise.

We do this by working on the underlying contradiction and applying a series of proven techniques to achieve an optimal outcome that satisfies both the customer and business objectives.

OUR METHODOLOGIES

THEORY OF INVENTIVE PROBLEM SOLVING (TRIZ)

The Theory of Inventive Problem Solving is based on the work of the late Genrich Altshuller and his team and the analysis of over 2 million inventive solutions over the last 60 years.

TRIZ holds to the idea that 99.9% of all creative solutions use an existing pattern and that these patterns are universal across industry domains.

Most improvement efforts take the path of random idea generation and brainstorming or extensive trial-and-error work to generate solutions. TRIZ, however, follows a robust systematic methodology for producing innovative solution ideas.

It provides breakthrough results for overcoming contradictions to some of the most difficult challenges in business today.

Click to view sample tools

LEAN SIX SIGMA (LSS)

Lean Six Sigma is the combination of two complementary methodologies, Lean and Six Sigma.

Lean takes its roots primarily from the Toyota Production System but includes contributions from many improvement experts. Its core theme is waste identification and removal to enhance production processes while reducing cost.

Six Sigma, on the other hand, is a methodology coined by Motorola to represent a formal quality program for reducing defects and variation. It relies on a robust deployment framework and uses specially trained improvement personnel to carry out its processes and drive change.

Lean Six Sigma is a separate methodology from Lean and Six Sigma, and brings together many of the tools and concepts of each under one complementary approach.

Click to view sample tools

THEORY OF CONSTRAINTS (TOC)

The Theory of Constraints is a management philosophy introduced by Eliyahu Goldratt, whereby organisations are seen as a system whose commercial function is to generate revenue. The source of that revenue, Throughput, is inhibited by constraints.

TOC views the traditional cost-world paradigm, where individual or project efforts are seen as aggregate, as one of the sources of constraints to organisational throughput.

The best way to think about a constraint is with the example of links in a chain. The chain will always be limited by its weakest link. Strengthening any other link in the chain but the weakest link will have no impact on the outcome. The same holds true for improvements made within an organisation.

The underlying assumption for improvement is that managing three key levers within the organisation can optimize revenue: Throughput, Operational Expense, and Inventory.

To that end, TOC focuses on a Throughput-world paradigm, directing improvement efforts to only those constraints, which will directly deliver value to the business.

Click to view sample tools